23 Jan Best Fiber Optic Cabling Installation Practices Guide

Construction Products Regulation (CPR) for Cables

- Plan the Installation: Before starting the installation, it is important to plan the route of the cable and to ensure that the conduit or other pathways are properly prepared to support the cable and the cost of cable installation.

- Handle the Cable Carefully: Fiber optic cables are delicate and can be easily damaged. It is important to handle the cable carefully and to avoid bending, twisting, or crushing the cable.

- Use the Right Tools: The installation process requires specialized tools, such as fiber optic cable cutters, strippers, and cleavers. It is important to use the right tools for the job to ensure a clean and precise cut.

- Clean the Connectors: Before connecting the cables, it is important to clean the connectors to remove any dust or debris that could cause signal loss.

- Test the Cable: After the cable has been installed, it is important to test the cable to ensure that it is functioning properly and that there are no breaks or other issues.

- Properly Label and Document: Properly label and document the cable runs, patch panels, and other components, to ensure that the system is easy to understand, troubleshoot and maintain.

- Follow safety guidelines: Fiber optic cables are sensitive to light and heat, wear protective gear and follow safety guidelines to avoid damage to the cable or harm to the installer.

- Training: It is important that the installers are trained and certified on fiber optic cabling installation and handling, this will help to ensure a successful and reliable installation.

How to make a Preparation for Our Fiber Cable Installation (Before we begin)?

- Plan the Route: Carefully plan the route of the cable and ensure that the conduit or other pathways are properly prepared to support the cable.

- Obtain Permits: Obtain any necessary permits, such as building permits or right-of-way permits, to ensure that the installation is in compliance with local regulations.

- Gather Materials and Tools: Gather all necessary materials, such as conduit, cable, connectors, and tools, such as fiber optic cable cutters, strippers, and cleavers, to ensure that the installation can proceed smoothly.

- Prepare the Work Area: Prepare the work area by clearing away any debris and ensuring that there is adequate lighting and power for the installation.

- Review Safety Procedures: Review safety procedures to ensure that the installation is done safely, and that the cable and the installers are protected from potential hazards.

- Identify any potential problems: Identify any potential problems that could arise during the installation, such as difficult access points or the presence of other utilities.

- Coordinate with other trades: Coordinate with other trades, such as electricians or plumbers, to ensure that the installation does not interfere with other work that is being done.

- Notify the building owner and tenants: Notify the building owner and tenants of the planned installation, to ensure that they are aware of the work that is being done and to minimize disruptions.

How to proceed with Installing Our Fiber Optic Cabling (When work is ready to begin)?

- Plan the installation route: Determine the most efficient and effective route for the fiber optic cable to be installed, taking into account factors such as building layout, potential obstacles, and local regulations.

- Prepare the installation site: Clear the installation route of any potential hazards or obstacles and ensure that the area is accessible.

- Install conduit or ducts: Run conduit or ducts along the planned route to protect the fiber optic cable from damage.

- Pull the fiber optic cable: Carefully pull the fiber optic cable through the conduit or ducts, making sure to avoid putting any tension on the cable.

- Connect the cable: Connect the fiber optic cable to the necessary equipment, such as patch panels and optical network terminals.

- Test the cable: Test the cable to ensure that it is properly connected and functioning.

- Document the installation: Document the installation by keeping a record of the cable route, the equipment used, and any issues that were encountered and resolved.

- Clean up: Clean up the installation site and dispose of any materials that were used in the installation.

Fiber Optic Service Loops

Construction Products Regulation (CPR) for Cables

Construction Products Regulation (CPR) for Cables CPR for cables (Construction Products Regulation) for cables became a legal requirement in July 2017. CPR for fiber optic cables is having an intended…

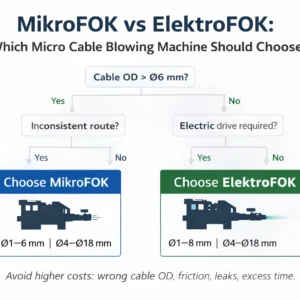

No comment 0 LikesMikroFOK vs ElektroFOK: Micro Cable Blowing Machine Selector

UPCOM • Cable Blowing Machines • FTTH / Microduct MikroFOK vs ElektroFOK: Which Micro Cable Blowing Machine Should You Choose? Choosing between MikroFOK and ElektroFOK for microduct work is mostly abo…

No comment 0 LikesOptical Fiber

What is Optical Fiber? Optical Fiber is a transmission technology that carries data as light through ultra-thin strands of glass or plastic. Unlike copper cables that transmit electrical signals, fibe…

No comment 8 Likes19″ Rack Cabinet Dimensions | 19-Inch Standard (U, Depth, Width)

19" Rack Cabinet Dimensions (19-Inch Standard Explained) A 19" rack cabinet is an enclosure built around the global 19-inch mounting standard used for servers, switches, patch panels and rac…

No comment 0 Likes5 Fan Facts About the Fiber Optic Cables

Construction Products Regulation (CPR) for Cables Fiber optic cables transmit data using light through glass or plastic fibers. Compared to copper cables, fiber delivers higher speed, longer transmiss…

No comment 4 LikesWhat is fiber optic cable

What is fiber optic cable? Fiber optic cables are an innovative communication medium that transmit data using light instead of electrical signals. Designed for efficiency and speed, these cables lever…

No comment 4 LikesFiber Optic Cable Installation Cost

Updated guide for telecom and infrastructure professionals (2026) Installing fiber optic cables remains one of the most critical phases of modern communication infrastructure. For project managers and…

No comment 4 LikesIP55 Outdoor Cabinet

IP55 Outdoor Cabinet We found out that there is no enough information about 19” IP55 Outdoor Cabinet and thus we will investigate it. If you are reading this article, then you are probably planning to…

No comment 3 LikesFTTH Installation Methods and Cost Reduction Strategies

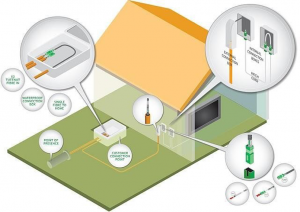

FTTH Installation Methods and Cost Reduction Strategies FTTH installation is not limited by fiber technology anymore, it is limited by civil works cost, access to existing infrastructure, and how effi…

No comment 1 LikeCable Blowing by Pressurized Air / Fiber Optic Cable Blowing Procedure

Fiber to the Home (FTTH): The 2026 Complete Guide to High-Speed Fiber Connectivity Cable blowing (also called air-assisted cable installation, jetting, or pressurized-air cable blowing) is one of the …

No comment 1 Like