25 Jan Tight-Buffered and Loose-Tube Cables

Tight-buffer cables

Tight-Buffer CablesThis is is a type of fiber optic cable in which the optical fibers are surrounded by a tight-fitting buffer material, such as a plastic coating, to protect them from external damage. This construction is typically for short-distance applications and provides a high level of protection for the fibers.The buffer material is usually made of a polymer, and it surrounds each optical fiber individually. This way, the fibers are protected from mechanical and environmental stresses, and it makes it easy to handle and terminate the fibers. Tight-buffer fibers are commonly used in indoor applications, such as in buildings, data centers, and campus networks, where the cable is protected from environmental factors such as water and UV radiation.Tight-buffer fiber cables are available in different types and sizes, such as simplex, duplex, and multi-fiber cables, and they can be for both single-mode and multi-mode fibers. They are also available in different colors, to distinguish different fibers, and they can be terminated with different connectors, such as LC, SC, and ST, to adapt to different applications.

Tight-Buffer CablesThis is is a type of fiber optic cable in which the optical fibers are surrounded by a tight-fitting buffer material, such as a plastic coating, to protect them from external damage. This construction is typically for short-distance applications and provides a high level of protection for the fibers.The buffer material is usually made of a polymer, and it surrounds each optical fiber individually. This way, the fibers are protected from mechanical and environmental stresses, and it makes it easy to handle and terminate the fibers. Tight-buffer fibers are commonly used in indoor applications, such as in buildings, data centers, and campus networks, where the cable is protected from environmental factors such as water and UV radiation.Tight-buffer fiber cables are available in different types and sizes, such as simplex, duplex, and multi-fiber cables, and they can be for both single-mode and multi-mode fibers. They are also available in different colors, to distinguish different fibers, and they can be terminated with different connectors, such as LC, SC, and ST, to adapt to different applications.Loose-Tube Cables

Loose-Tube Cables

What is the purpose of buffer tubes in fiber optic cable? Tight-Buffered and Loose-Tube Cables

What are the advantages of loose-tube fiber optic cables compared to tight-buffer fiber optic cables?

Loose-tube fiber optic cables have several advantages over tight-buffer cables, including:- Increased flexibility: Loose-tube cables are more flexible than tight-buffer cables, which makes them easier to install and handle in tight spaces.

- Better protection: The loose-tube design provides better protection for the fibers inside the cable, as they are not in direct contact with the cable jacket. This can help to reduce the risk of fiber damage during installation or handling.

- Better temperature performance: Loose-tube cables have a better temperature performance than tight-buffer cables, as the fibers are not in direct contact with the cable jacket. This means that they can operate in a wider range of temperatures.

- Better water resistance: Loose-tube cables have a better water resistance than tight-buffer cables, due to the gel filling inside the tube that exclude water penetration.

- Better flame resistance: Loose-tube cables have a better flame resistance than tight-buffer cables, as the fibers are not in direct contact with the cable jacket.

- More fibers per cable: Loose-tube cables can generally accommodate more fibers per cable than tight-buffer cables, which means that they can support higher bandwidths.

Fiber Optic Cable

In which application would you not normally use loose tube fiber?

Loose tube fiber optic cables are typically not used in indoor, short-distance, and low-stress applications.Because loose tube fiber optic cables are designed to withstand harsh environmental conditions and to allow the fibers to move freely within the cable, they are more suitable for outdoor and long-distance applications, such as underground and aerial installations, where the cable is exposed to the environment. They are also used in submarine communications and in harsh industrial environments.In contrast, tight-buffer fiber optic cables are designed to protect the fibers from mechanical stress and to make them easy to handle and terminate, they are more suitable for indoor, short-distance, and low-stress applications, such as in buildings, data centers and campus networks, where the cable is protected from environmental factors such as water and UV radiation.It’s important to note that the choice of the type of fiber optic cable depends on the specific requirements of the application, such as the transmission distance, data rate, and environmental factors.What are the loose tube fiber optic cables types?

- Central strength member (CSM) loose tube fiber optic cables: These cables feature a central strength member, typically made of steel or aramid, which provides the cable with mechanical strength and protection. The fibers are placed inside loose-fitting tubes, which are surrounded by the central strength member and a jacket. This type of cable is commonly used in aerial and underground applications.

- Jelly-filled loose tube fiber optic cables: These cables feature fibers that are placed inside loose-fitting tubes that are filled with a jelly-like material. The jelly provides additional protection for the fibers and helps to seal the tubes, making the cable more resistant to water and other environmental factors. This type of cable is commonly used in submarine and underground applications.

- Dry water-blocked loose tube fiber optic cables: These cables feature fibers that are placed inside loose-fitting tubes that are dry and water-blocked. This means that the fibers are not surrounded by any gel or liquid, but instead, a water-blocking material is used to prevent water from penetrating the cable. This type of cable is commonly used in outdoor and buried applications.

- Steel tape armored loose tube fiber optic cables: This type of loose tube fiber optic cables use steel tape as an armored layer for increased strength, durability and protection against physical damage. This type of cable is commonly used in harsh industrial environments, and where the cable is exposed to extreme temperatures.

- Loose tube with metallic central strength member (MCM): This type of loose tube fiber optic cables uses a metallic material as a central strength member, which provides additional mechanical protection, and it is suitable for high temperature applications and harsh environments.

What are the tight-buffer fiber optic cables types?

There are several types of tight buffer fiber optic cables, each with its own set of characteristics and applications. Some of the main types of tight buffer fiber optic cables include:- Simplex tight buffer fiber optic cables: These cables feature a single optical fiber surrounded by a tight-fitting buffer material, such as a plastic coating. This type of cable is commonly for short-distance applications, such as in buildings, data centers and campus networks.

- Duplex tight buffer fiber optic cables: These cables feature two optical fibers surrounded by a tight-fitting buffer material, such as a plastic coating. The fibers are typically have color-coded for easy identification. This type of cable is commonly used for short-distance applications, such as in buildings, data centers and campus networks.

- Multi-fiber tight buffer fiber optic cables: These cables feature multiple optical fibers surrounded by a tight-fitting buffer material, such as a plastic coating. The fibers have typically color-codes for easy identification. This type of cable is commonly for short-distance applications, such as in buildings, data centers and campus networks.

- Tight buffer with aramid yarn strength member (AYSM): This type of tight buffer fiber optic cables use aramid yarn as a strength member, which provides additional mechanical protection, and it is suitable for high-temperature and harsh environments.

- Tight buffer with Kevlar strength member: This type of tight buffer fiber optic cables use Kevlar as a strength member, which provides additional mechanical protection, and it is suitable for high-temperature and harsh environments

- A breakout cable is a type of tight buffer fiber optic cable that features multiple fibers surrounded by a tight-fitting buffer material, such as a plastic coating. The fibers have typically color-codes for easy identification. The fibers are grouped together in a common buffer and are separated at one or both ends of the cable to enable them to be connected to individual devices. This type of cable is commonly for short-distance applications, such as in buildings, data centers and campus networks.

- A minibreakout cable is similar to a breakout cable but it is smaller in size. They are typically for in high-density applications where space has limitation.

What are the european and international standards for loose tube fiber optic cables?

There are several European and international standards for loose tube fiber optic cables, that specify the requirements for the design, performance, and testing of the cables:- IEC 60794-1-2: This is an international standard that specifies the characteristics of optical fibers and cables. It covers the general requirements and test methods for optical fibers and cables, including loose tube fiber optic cables.

- EN 50173: This is a European standard that covers the specifications and test methods for cabling systems. It covers the requirements for the design, installation, and testing of optical fiber cabling systems, including loose tube fiber optic cables.

- IEC 60794-1-2: This standard specifies the requirements for the design, performance, and testing of optical fibers and cables, including loose tube fiber optic cables.

- TIA/EIA-455-51A: This is a TIA (Telecommunications Industry Association) and EIA (Electronic Industries Alliance) standard that covers the requirements for the design and testing of optical fiber cables, including loose tube fiber optic cables.

- IEC 60794-4-41: This standard specifies the requirements for the design and testing of optical fiber cables for use in outdoor and underground environments, including loose tube fiber optic cables.

What are the european and international standards for tight-buffer fiber optic cables?

There are several European and international standards for tight-buffer fiber optic cables. Some of the main ones include:- IEC 60793-2-10 – This international standard specifies the general requirements and test methods for optical fibers and cables, including tight-buffer cables.

- EN 50173-1 – This European standard provides guidelines for the planning, installation and management of optical fiber cabling in building and campus environments. It covers both loose-tube and tight-buffer cables.

- TIA/EIA-568-C.3 – This American standard is widely adopted in Europe and other parts of the world, it covers commercial building telecommunications cabling for customer premises, including tight-buffer fiber optic cables.

- ISO/IEC 11801-2 – This international standard covers cabling for customer premises and provides guidelines for the planning, installation, testing, and maintenance of optical fiber cabling systems. It covers both loose-tube and tight-buffer cables.

- IEC 61754-4 – This international standard covers the mechanical interfaces of optical connectors and adaptors, including those used with tight-buffer fibers.

Conclusion (Tight-Buffered and Loose-Tube Cables):

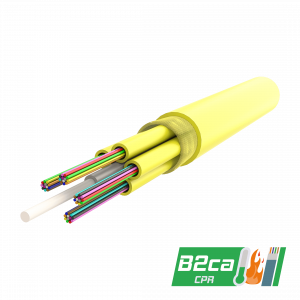

Construction Products Regulation (CPR) for Cables

CPR for cables (Construction Products Regulation) for cables became a legal requirement in July 2017. CPR for fiber optic cables is having an intended use for permanent installation in buildings and c…

No comment 0 LikesOptical Fiber

What is optical fiber? We are used to the concept of moving knowledge in numerous ways. A wire cable transports the sounds from our speech into a socket on the wall and is borne by another cabl…

No comment 8 Likes19″ Rack Cabinet

What is a 19” Free Standing Rack Cabinet? 19” free standing rack cabinets provide a robust, cost-effective enclosure solution. PDU mounting or connectivity on both the front and rear of the cabinet. T…

No comment 0 Likes5 Fan Facts About the Fiber Optic Cables

Fiber optic cables are a type of cable that use glass or plastic fibers to transmit data. Here are some interesting facts about fiber optic cables: Speed: Fiber optic cables are capable of transmittin…

No comment 4 LikesWhat is fiber optic cable

Fiber optic cables are an innovative communication medium that transmit data using light instead of electrical signals. Designed for efficiency and speed, these cables leverage thin strands of glass o…

No comment 4 LikesHow Much Does Fiber Optic Cable Installation Cost in 2025?

Fiber Optic Cable Installation Cost | Reduce Costs with Cable Blowing Machines – UPCOM How Much Does Fiber Optic Cable Installation Cost? Updated guide for telecom and infrastructure professionals (20…

No comment 4 LikesIP55 Outdoor Cabinet

We found out that there is no enough information about 19” IP55 Outdoor Cabinet and thus we will investigate it. If you are reading this article, then you are probably planning to make a procurement s…

No comment 3 LikesFTTH installation Technologies

FTTH installation technologies Table of Contents Innovative approach to FTTH installation Technologies…1 Infrastructure Sharing…2 Duct sharing in France…2.1 Sewer pipes…2.2 Cle…

No comment 1 LikeCable Blowing by Pressurized Air / Fiber Optic Cable Blowing Procedure

Cable Blowing (Sometime called air assisted cable blowing, Cable Blowing by Pressurized Air, air blowing, jetting and all these words are describing method of cable blowing with pressurized air) Cabl…

No comment 1 LikeWhat Distributors Should Know Before Importing Fiber Optic Products: A Technical & Manufacturer-Level Guide

A technical guide for distributors importing fiber optic products, covering manufacturer-level engineering standards, CPR compliance, blowing performance and key quality checks….

No comment 0 Likes