08 Feb Cable Spooling Machines: The Ultimate Guide to Efficient Cable Handling

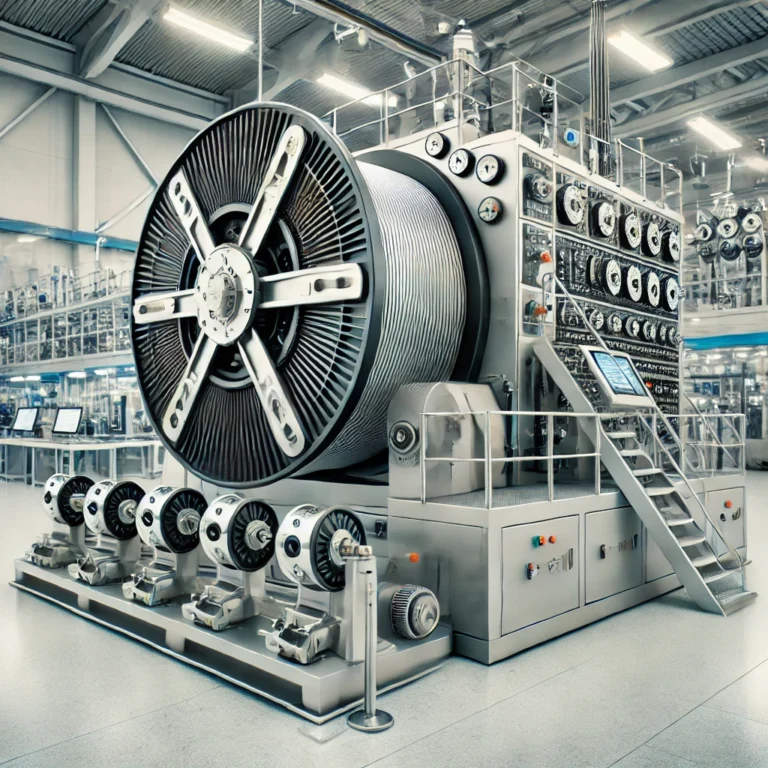

In industries such as telecommunications, energy, manufacturing, and infrastructure, the need for Cable Spooling Machines have never been greater. Traditional manual spooling methods can lead to inconsistencies, labor-intensive processes, and increased cable damage. This is where cable spooling machines revolutionize operations by ensuring precise, automated, and efficient winding and unwinding of cables.

Cable spooling machines, also referred to as cable winding machines, play a critical role in optimizing cable transfer, coiling, and storage. Whether used in fiber optics, electrical cabling, or industrial wire applications, these machines reduce waste, increase production speed, and enhance cable quality.

This guide explores the different types of cable spooling machines, their benefits, technical features, and how Upcom’s advanced solutions can help businesses improve cable handling efficiency.

📌 Reference: Cable spooling system

What is a Cable Spooling Machine?

A cable spooling machine is a mechanized system designed to wind, unwind, transfer, and neatly store cables onto reels or spools. These machines minimize tension, prevent damage, and ensure uniform winding, making them ideal for large-scale cable production and distribution.

How Cable Spooling Machines Work

- Cable Feeding – The machine draws in the cable from a supply source.

- Tension Control – Automatic tension management ensures uniform winding and prevents stretching.

- Spooling/Winding – The system precisely winds the cable onto a reel, adjusting speed and tension as needed.

- Cutting & Packaging – Some models include automated cutting systems for pre-set cable lengths.

Benefits of Using Cable Spooling Machines

1️⃣ Increased Efficiency & Automation

- Enables continuous cable handling without manual intervention.

- Reduces workforce costs and production time.

📌 Case Study: A German telecom company doubled production capacity with high-speed cable spooling automation.

2️⃣ Precision Winding & Cable Protection

- Ensures uniform tension, preventing cable deformation and breakage.

- Reduces wear and tear, extending cable lifespan.

- Prevents kinks, knots, and twists for seamless deployment.

📌 Reference: European Cable Industry Reports – Cable Handling Trends

3️⃣ Versatile Applications

- Suitable for fiber optics, electrical wiring, industrial cables, and flexible tubing.

- Handles various cable diameters and different reel sizes.

📌 Example: A European aerospace company uses high-precision spooling machines to handle sensitive fiber optic cables.

4️⃣ Safety & Ergonomic Handling

- Reduces the risk of operator injuries from heavy cable reels.

- Improves workplace safety compliance.

- Minimizes operator fatigue, especially in high-volume production facilities.

Types of Cable Spooling Machines & Upcom’s Solutions

1️⃣ Fully Automatic Cable Spooling Machines

- Fully automated control for high-speed production lines.

- Tension-controlled winding ensures precise coiling.

🔗 Recommended Model: Upcom AutoSpool 500 – Ideal for large-scale industrial applications.

2️⃣ Semi-Automatic Cable Winding Machines

- Operator-assisted control with adjustable speed settings.

- Suitable for medium-volume cable manufacturers.

🔗 Recommended Model: Upcom SemiSpool 300 – Best for flexible cable handling needs.

3️⃣ Manual Cable Reeling Machines

- Designed for small-scale operations and portable use.

- Hand-crank or motorized models available.

🔗 Recommended Model: Upcom HandSpool 150 – Ideal for low-volume projects.

How to Choose the Right Cable Spooling Machine

Key Considerations Before Buying

- Cable Type & Diameter – Ensure compatibility with fiber optic, copper, or industrial cables.

- Spooling Speed & Automation Level – Choose between manual, semi-automatic, or fully automated models.

- Reel Size & Load Capacity – Consider the maximum reel diameter and weight the machine can handle.

- Tension Control System – Look for models with adjustable tension settings to prevent cable stretching.

- Portability & Workspace Constraints – Some models are compact and mobile, while others are designed for factory environments.

📌 Example: A Turkish cable distributor increased output efficiency by 30% after upgrading to Upcom’s automated spooling system.

Future Trends in Cable Spooling Technology

With the rapid advancement of Industry 4.0 and smart manufacturing, cable spooling machines are evolving to include:

- AI-powered quality control systems to detect spooling errors in real time.

- IoT-integrated monitoring for remote performance tracking.

- Eco-friendly designs that reduce material waste and energy consumption.

📌 Industry Forecast: By 2030, over 85% of cable manufacturers in Europe will rely on fully automated spooling systems for improved efficiency.

Cable spooling machines are essential for businesses looking to improve efficiency, precision, and safety in cable handling operations. Whether for small-scale workshops or high-volume industrial production, the right cable spooling machine can streamline workflow and reduce operational costs.

🔗 Explore Upcom’s full range of cable spooling machines here and optimize your cable management today! 🚀