15 Dez Fiber Optic Blowing Tips

Fiber Optic Blowing Tips – 7 important points

7 Fiber Optic Blowing Tips – Fiber optic Cable blowing is a specialized process involving the use of pressurized air to install cables into telecom ducts. This method is highly effective for blowing the fiber optic cables far away but requires careful preparation and execution to ensure success. Below, we explore the most important considerations to maximize cable blowing efficiency, minimize risks, and achieve optimal results.

1. Prioritize Safety First

Safety is non-negotiable in cable blowing operations. Ensure all technicians are properly trained and equipped with the necessary personal protective equipment (PPE), including:

- Eye protection

- Ear muffs

- Helmets

- Protective suits

Communication between all workstations is essential. Test and confirm all safety signals (e.g., “STOP” or “RUN”) before starting the machinery. Additionally, always depressurize the system before handling connections to avoid injury.

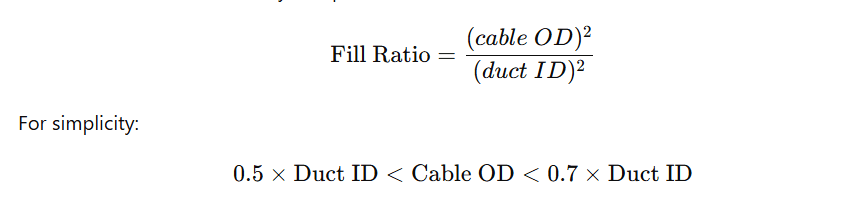

2. Use Compatible Cable and Duct Sizes

The compatibility of cable and duct sizes is critical for smooth installation. Aim for a fill ratio of 30-50%, which balances efficiency and performance. To calculate this ratio:

Incompatible sizes can cause blockages, reduce airflow efficiency, and lead to cable damage.

3. Protect and Prepare Your Cable

Before blowing, ensure your cable is well-protected against environmental factors:

- Use a cable cap to prevent high-pressure air from penetrating the cable.

- Store the cable drum on a suitable pay-off stand to prevent tangles and damage.

- Shield the cable from water, dust, and direct sunlight during the installation process.

4. Verify and Adjust Your Cable Blowing Machine

Proper setup of your cable blowing machine is essential. Verify the following:

- Compatibility: Ensure the machine, accessories, and compressor match the cable and duct specifications.

- Airflow and Pressure: Confirm the machine can deliver the required airflow and pressure for the job.

- Connections: Use suitable seals, nut rings, and duct connectors.

Additional Tips:

- A drier and air cooler between the compressor and machine improve efficiency by maintaining clean, dry air.

- Always ensure the pay-off stand is compatible with the cable drum size.

5. Choose the Right Compressor

Selecting the appropriate air compressor for the duct size is crucial. Here’s a quick reference guide:

| Duct Size (mm) | Airflow (m³/min) | Max Pressure (bar) | Recommended Compressor |

|---|---|---|---|

| 8 | 0.8 | 15 | Kaeser M13 |

| 8-12 | 1.0 | 15 | Kaeser M17 |

| 12-15 | 1.5-2.5 | 7 or 14 | Kaeser M17 |

| 15-20 | 3.5-5.0 | 7 or 10 | Kaeser M125 |

| 32-50 | 7-11 | 7 or 10 | Kaeser M120 |

Ensure the compressor meets the required specifications to avoid under- or over-pressurizing the system.

6. Prepare the Duct

A clean, obstruction-free duct is vital for successful cable blowing. Follow these steps:

- Gauge Test: Use a measuring device to check for damage or deformation in the duct.

- Cleaning: Run sponges through the duct to remove dirt and moisture. Repeat if necessary until the duct is clean and dry.

Pro Tip: Avoid sharp bends and connectors in the duct path as they can limit the blowing distance.

7. Optimize the Blowing Procedure

Start the blowing operation with careful adjustments to speed and pressure:

- Begin pushing the cable at 40-60 m/min without applying air pressure.

- Gradually increase the air pressure to 1-2 bars to restore speed when it slows down.

- If progress halts, release the air pressure, wait a few minutes, and restart. Repeat as needed.

When Distance Is a Challenge:

- Stop the machine and release pressure.

- Let the system stabilize for 5 minutes, then reapply air at maximum pressure.

- Resume blowing to cover the remaining distance.

Additional Tips

- Use Lubricants: Special lubricants designed for cable jetting reduce friction and enhance performance.

Kabelblasen-Schmiermittel UP S LUB 20

Cable Blowing Lubricant UP S LUB 100XL

- Monitor Conditions: Check weather conditions like wind, rain, and temperature, as they can affect air pressure and the cable’s trajectory.

- Remote Monitoring: For long-distance installations, use monitoring systems to identify and resolve issues in real-time.

By following these detailed guidelines, you can ensure a smooth, efficient, and successful fiber optic cable blowing process, even for the most challenging long-distance installations.

Dies sind einige wichtige Tipps zum Einblasen von Kabeln, die Sie sich merken sollten. Nachfolgend finden Sie einige Einrichtungsvideos von unseren Maschinen;

Tipps zum Kabelblasen

11 Gründe, warum die Zukunft der Glasfasertechnik gehört

11 Reasons Why the Future Belongs to Fiber Optic “The future belongs to fiber optics!” This bold claim is backed by compelling reasons. Fiber optic technology is not just an upgrade—it’s a transformative infrastructure shaping how we connect, communicate, and consume information. Here are 11......

19″ Rack Kabinett

What is a 19” Free Standing Rack Cabinet? 19” free standing rack cabinets provide a robust, cost-effective enclosure solution. PDU mounting or connectivity on both the front and rear of the cabinet. The Free Standing 19” Rack cabinets are ideal for high-density data center environments,......

5 Fan Facts About the Fiber Optic Cables

Fiber optic cables are a type of cable that use glass or plastic fibers to transmit data. Here are some interesting facts about fiber optic cables: Speed: Fiber optic cables are capable of transmitting data at much faster speeds than traditional copper cables. This makes......

Advancements in Fiber Optic Technology: Improving Bandwidth and Transmission Rates

Fiber optic technology has revolutionized the way we communicate, providing faster and more reliable data transmission over long distances. The use of fiber optic cables has become increasingly popular in recent years, and the technology continues to evolve at a rapid pace. In this article,......

Alles über Glasfaseroptik

What does a fiber optic cable do? A fiber optic cable is a type of cable that uses glass or plastic threads to transmit data. These threads, or fibers, are extremely thin and are surrounded by a protective coating. They are able to transmit data......

Leitfaden für die besten Praktiken bei der Installation von Glasfaserkabeln

Fiber optic cabling installation is a complex process that requires specialized knowledge and equipment. Here are some best practices for fiber optic cabling installation to ensure a successful and reliable installation: Plan the Installation: Before starting the installation, it is important to plan......

Einblasen von Kabeln mit Druckluft / Einblasverfahren für Glasfaserkabel

Cable Blowing (Sometime called air assisted cable blowing, Cable Blowing by Pressurized Air, air blowing, jetting and all these words are describing method of cable blowing with pressurized air) Cable Installation has been always a challenge for installers. There are several method to lay the......

Kabel-Schmiermittel

Cable blowing lubricants are specially formulated lubricants used to lubricate cables as they are being pulled through conduits or other tight spaces during the installation process. The lubricant is applied to the cables before they are pulled, and it helps to reduce friction and make......

Kabel Einblasmaschine Arbeit

Cable Blowing Machines here Click here to find out Cable Blowing Machine Product Portfolio Click Here Cable blowing machines, also known as a jetting machine or fiber optic cable blowing machine, is a device used to blow cables, such as fiber optic cables, into ducts......

Cable Spooling Machines: The Ultimate Guide to Efficient Cable Handling

In industries such as telecommunications, energy, manufacturing, and infrastructure, the need for Cable Spooling Machines have never been greater. Traditional manual spooling methods can lead to inconsistencies, labor-intensive processes, and increased cable damage. This is where cable spooling machines revolutionize operations by ensuring precise, automated, and......