Data Center Environmental Monitoring & Control Solutions

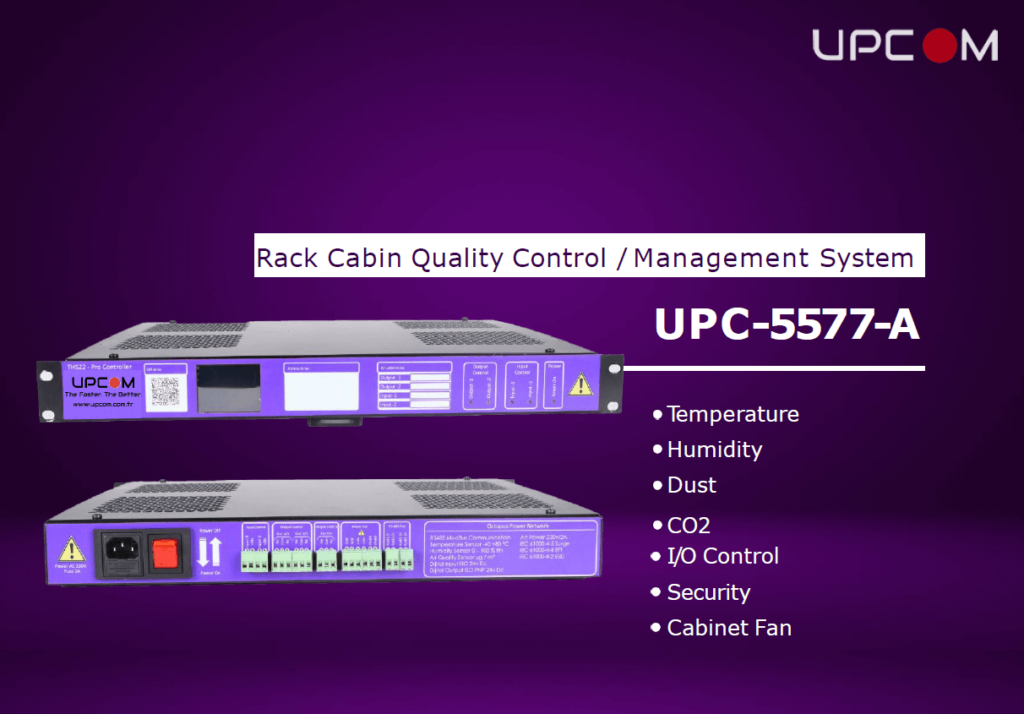

Environmental monitoring systems (EMS) are essential for businesses that rely on data centers to store and manage critical information. These systems use various sensors to monitor environmental factors such as temperature, humidity, dust levels, CO2 levels, and I/O control, which can affect the performance and lifespan of data center equipment.

Temperature sensors are a critical component of an EMS as they help maintain optimal operating temperatures for data center equipment. High temperatures can cause equipment to overheat and fail, leading to costly downtime. By monitoring temperature levels, businesses can take preventive measures to protect their equipment and prevent downtime.

Humidity sensors are equally important as high humidity levels can cause condensation to form on equipment, leading to damage and downtime. By monitoring humidity levels and taking corrective action, such as increasing ventilation or adjusting cooling systems, businesses can maintain a safe and optimal operating environment for their equipment.

Dust sensors are crucial for protecting data center equipment from dust and small particles that can accumulate on equipment and cause damage over time. By monitoring dust levels, businesses can take preventive action, such as increasing air filtration or reducing air flow, to reduce the risk of equipment damage and extend the lifespan of their equipment.

CO2 sensors are essential for detecting high levels of CO2, which can be an indicator of high levels of dust and small particles in the air. By monitoring CO2 levels and taking corrective action, such as increasing ventilation or reducing the amount of equipment in a confined space, businesses can reduce the risk of equipment damage and improve overall air quality.

Finally, I/O control is necessary for managing power and communication systems in the data center. By monitoring and controlling I/O operations, businesses can ensure that their equipment is operating efficiently and reduce the risk of equipment failure.

In conclusion, environmental monitoring systems are vital for protecting data center equipment and maintaining optimal operating conditions. Temperature, humidity, dust, CO2, and I/O control sensors are crucial components of these systems as they allow businesses to monitor and manage environmental factors that can affect the performance and lifespan of their equipment. By investing in an EMS, businesses can improve operational efficiency, reduce downtime, and protect their critical data.

Importance of EMS

Environmental monitoring systems (EMS) play a crucial role in ensuring the smooth operation of data centers, which are essential for modern businesses. These systems use a variety of sensors to monitor environmental factors, including temperature, humidity, dust levels, CO2 levels, and I/O control, to maintain optimal operating conditions for data center equipment.

Temperature sensors

Temperature sensors are critical for maintaining the correct operating temperature for equipment. High temperatures can lead to equipment overheating and failure, resulting in costly downtime. By monitoring temperature levels, EMS can ensure that the temperature remains within the optimal range, and corrective action can be taken if necessary.

Humidity sensors

Humidity sensors are equally important as high humidity levels can cause condensation to form on equipment, leading to damage and downtime. By monitoring humidity levels and taking corrective action, businesses can maintain a safe and optimal operating environment for their equipment.

Dust sensors

Dust sensors are crucial for protecting data center equipment from dust and small particles that can accumulate on equipment and cause damage over time. By monitoring dust levels, businesses can take preventive action, such as increasing air filtration or reducing air flow, to reduce the risk of equipment damage and extend the lifespan of their equipment.

CO2 sensors

CO2 sensors play a crucial role in detecting high levels of CO2, which can indicate high levels of dust and small particles in the air. By monitoring CO2 levels and taking corrective action, businesses can reduce the risk of equipment damage and improve overall air quality. In a data center environment, high levels of dust and small particles can cause significant damage to equipment and lead to costly downtime. The CO2 sensor plays a critical role in preventing this damage by detecting high CO2 levels, which can be an indicator of high levels of dust and small particles in the air.

Conculusion

Finally, I/O control is necessary for managing power and communication systems in the data center. By monitoring and controlling I/O operations, businesses can ensure that their equipment is operating efficiently and reduce the risk of equipment failure.

In conclusion, environmental monitoring systems are essential for ensuring the smooth operation of data centers. Temperature, humidity, dust, CO2, and I/O control sensors are critical components of these systems as they allow businesses to monitor and manage environmental factors that can affect the performance and lifespan of their equipment. The CO2 sensor, in particular, is vital for protecting data center equipment from dust and small particles and preventing costly downtime. By investing in an EMS, businesses can improve operational efficiency, reduce downtime, and protect their critical data.

Advantages of Environmental monitoring systems

Environmental monitoring systems (EMS) provide a range of advantages for businesses that rely on data centers, including:

Improved equipment reliability: EMS sensors, such as temperature, humidity, and dust sensors, can help detect potential issues before they lead to equipment failure or downtime. By monitoring environmental factors that can affect equipment performance, businesses can take proactive steps to ensure their equipment remains in good working order and avoid costly repairs or replacements.

Reduced downtime: By providing real-time data on environmental conditions, an EMS can help businesses detect and respond to potential issues before they escalate, reducing the risk of downtime and its associated costs in terms of lost productivity and revenue.

Energy efficiency: An EMS can help businesses optimize energy usage and reduce cooling costs by automating temperature control and adjusting cooling systems based on real-time data.

Improved environmental sustainability: By reducing energy usage and optimizing cooling systems, an EMS can help businesses reduce their carbon footprint and improve their environmental sustainability.

Data-driven decision-making: An EMS provides businesses with a wealth of real-time data on environmental conditions that can inform decision-making and help identify opportunities for improvement in areas such as equipment maintenance, energy usage, and cooling system design.

Compliance with industry regulations: Many industries have regulations governing the temperature, humidity, and other environmental conditions in data centers. An EMS can help businesses ensure compliance with these regulations and avoid potential penalties.

Overall, an EMS provides businesses with valuable insights and tools for monitoring and managing the environmental conditions that are critical to the reliable and efficient operation of their data centers. The advantages of these systems include improved equipment reliability, reduced downtime, energy efficiency, improved environmental sustainability, data-driven decision-making, and compliance with industry regulations.

How profitful are the Environmental monitoring systems?

The profitability of an environmental monitoring system (EMS) depends on several factors, including the size and complexity of the data center, the types of sensors used, and the level of automation in the system.

While an EMS can require a significant upfront investment, it can provide a range of benefits that can result in long-term cost savings and improved profitability for businesses. For example, by monitoring and managing environmental factors such as temperature, humidity, and dust levels, businesses can reduce the risk of equipment failure and downtime, which can be extremely costly in terms of lost revenue and productivity.

Additionally, an EMS can help businesses optimize energy usage, reduce cooling costs, and improve overall efficiency, which can lead to significant cost savings over time. By automating tasks such as temperature and humidity control, businesses can also reduce the need for manual monitoring and intervention, which can free up staff time and improve operational efficiency.

Furthermore, an EMS can help businesses improve the reliability and lifespan of their equipment, which can reduce the need for frequent equipment replacements and repairs, resulting in cost savings and improved profitability.

In summary, while the initial investment in an EMS may seem significant, the potential long-term benefits in terms of cost savings, improved efficiency, and equipment reliability can make it a profitable investment for businesses.