09 May Cable Blowing Machine work

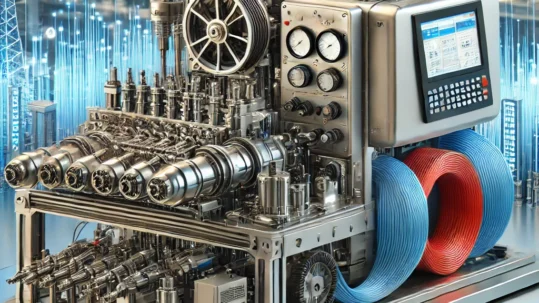

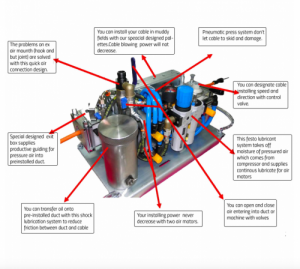

The basic components of a cable blowing machine include a compressor or pump, a hose, and a blowing head. The compressor or pump generates the high-pressure air or water needed to propel the cable, while the hose is used to guide the cable from the machine to the conduit. The blowing head is the device at the end of the hose that directs the high-pressure air or water onto the cable, propelling it through the conduit.

To use a cable blowing machine, the operator first attaches the cable to the blowing head and feeds it into the conduit. The machine is then turned on, and the high-pressure air or water is used to propel the cable through the conduit. The operator guides the cable as it moves through the conduit, ensuring that it is properly positioned and that there are no kinks or twists in the cable.

Cable blowing machines are typically used in the telecommunications, construction, and utility industries, and are widely used in the installation and maintenance of fiber optic cables and other types of cables. They are useful when installing cables in hard-to-reach areas, such as underground or in tight spaces, and can save time and money on large-scale cable installation projects.

In summary, a cable blowing machine, also known as a jetting machine or fiber optic cable blowing machine, is a device used to blow cables, such as fiber optic cables, into ducts or conduits. It works by using high-pressure air or water to propel the cable through the conduit, allowing for quick and efficient installation. Cable blowing machines are typically used in the telecommunications, construction, and utility industries, and are widely used in the installation and maintenance of fiber optic cables and other types of cables.

———————

How Does A Cable Blowing Machine Work and what is Cable blowing machine also called Jetting machine or fiber optic cable blowing machine. The fiber optic cable blowing machines are engineered and manufactured for deploying and installing the fiber optic cables into ducts (micro-ducts or HDPE telecom ducts) by the help of of pressurized air or compressed air. After that, Cable is put into a motorized cable blower head that is plugged to a duct via a one-way air valve.

The pusher head provides the initial pushing force that drives the cable into duct when air source like compressor is introduced to the duct through the one-way air valve. Then Hydraulic or Pneumatic motors will help to push the cable into ducts and compressed air will decrease the friction of cable by preventing the cable contacting ducts. Therefore, the cable can be pushed through thousands of kilometer of pre-installed duct. Such long distances are possible with the high air drag and low friction generous. So it will be good to use Lubricant Oil. To reduce friction between cable and duct, you can consider to add special lubricant into ducts.

On the other hand it might be good idea to use an Air Cooler for more safe cable blowing.

Air Cooler:

Air Cooler remarkably effects and increases the “blowing” performances and protects the cable from the high temperature with the cooling feature of this accessory when climate temperature exceeds 20°C.

Air Cooler Machine is very much recommended making a safe cable deployment in long distances without or with less friction and this will protect your cable from the potential damages that are mainly high temperature on the cable jacket surface. This heat may cause to melding of cable jacket and cost you high.

Special mechanism of machine changes the high temperature air with the air outside. The pressurized cool air will drive the fan that propels the air outside with low temperature.

This machine should be between the air-compressor and the cable blowing machine, which limits the pressurized air’s temperature up to max around 10°C more than the air in the climate in order to prevent the overheating problems.

Without air cooler, the temperature of compressed air exiting the compressor is around 35°C above the ambient temperature.

In case no air cooler, then the air temperature compressed may exceed the environment temperature by 30 or 35C.. This means that total temperature may go up to 70C. Such a temperature will meld the outer jacket of cable.

Any temperature more than 50°C, will soften the outer sheath of cable and also pre-installed duct walls. Due to aforesaid reasons your cable deployment time and cost will remarkably increase, length of cable you install will be much less. This will bring the risk of bursting of ducts.

Blowing machine design

Fiber Optic cable blowing machine mainly consists of following parts

- Adjustment and lubrication mechanism

- Mechanical or digital cable meter counter

- Pressurized air plug or connection

- Cable router

- Base line plate or basement

- Pallet and or belt feeder mechanism

- Pushing head

A Fiber cable blowing machine consists of the following components:

- a head that is assuring secure fitting of the duct that we will install the cable inside. It is going to be providing the medium (Air/Pneumatic or Oil/Hydraulic) to the HDPE telecom ducts. Afterwards the fiber cable pushed into the HDPE duct through the head goes inside a sealing system preventing the medium from getting into the machine;

- a pallet or belt feeder which pushes the cable forward the head;

- a basement plate or a frame onto which the cable blowing machine’s subsystems are assembled

- cable router, which is a system of bushes or rolls routing the cable forward the blowing head;

- air or oil supply is ensued to the blowing machine securely;

- a digital or mechanical meter counter which shows the length (in some cases the cable velocity) of the installed cable

- and control unit which helps you to control cable speed blown and the propelling power of the feeder.

Types

Machines are classified with regard to the diameter of the cable they can handle and the type of drive system (track feeder, roller feeder, belt feeder or blower heads without feeders). The machines are of 2 types.

- Hydraulically powered

- Pneumatically powered.

The hydraulically blowing machine consists of 2 parts.

- Cable feeding unit: – This is the main component and it pushes the cable into the HDPE duct with the help of compressed air.

- Hydraulic Power pack: – This unit provides the power to cable feeding unit and it is because of hydraulic power pack, the cable feeding unit operates.

How does a cable blowing machine work?

- 10Dec

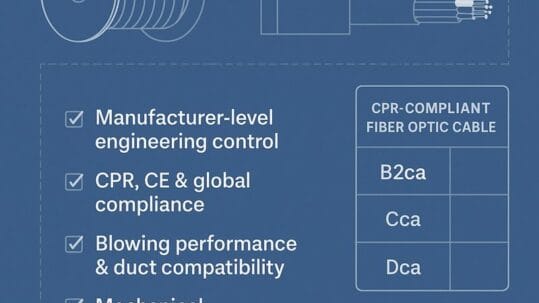

What Distributors Should Know Before Importing Fiber Optic Products: A Technical & Manufacturer-Level Guide

A technical guide for distributors importing fiber optic products, covering manufacturer-level engineering standards, CPR compliance, blowing performance and key quality checks....

Fiber Optic Cables No comment - 10Dec

Fiber Blowing Best Practices: The Complete Engineering Checklist for High-Performance Deployments

Efficient fiber blowing is not only about using a powerful machine or high-quality fiber. Field performance depends on engineering discipline: correct duct–cable pairing, airflow capacity, lubrication strategy, mechanical limits, and environmental planning. This guide provides a complete engineering checklist used by professional FTTx, OSP, and......

Cable Blowing No comment - 22Nov

Security in Server Cabinet Racks: Protecting Your Critical Infrastructure

Ensuring the security and operational continuity of network equipment is a fundamental priority for modern IT environments. As organizations grow their digital operations, server cabinets evolve into engineered protection systems designed to safeguard mission‑critical infrastructure. Why Robust Security Matters Server cabinets house valuable hardware that......

Server Cabinets Rack No comment - 19Feb

How to Blow Fiber Optic Cable: A Comprehensive Fiber Jetting Guide

Table of Contents Introduction to fiber optic cable blowing Required Equipment and Tools Understanding Fiber Blowing Machines and Their Components Preparing for the Fiber Blowing Process Safety Precautions Before Starting Step-by-Step Fiber Optic Cable Blowing Procedure 6.1 Setting Up the Fiber Blowing Machine 6.2 Preparing......

Cable Blowing Machine No comment - 08Feb

Cable Spooling Machines: The Ultimate Guide to Efficient Cable Handling

In industries such as telecommunications, energy, manufacturing, and infrastructure, the need for Cable Spooling Machines have never been greater. Traditional manual spooling methods can lead to inconsistencies, labor-intensive processes, and increased cable damage. This is where cable spooling machines revolutionize operations by ensuring precise, automated, and......

machine No comment - 07Feb

Fiber Optic Network Optimization: How to Improve Performance in High-Density Urban Areas

As urban populations grow and the demand for high-speed internet continues to increase, telecom operators face the challenge of optimizing fiber optic network performance in high-density urban environments. Fiber optic network optimization is crucial to ensure seamless connectivity, reduce latency, and manage bandwidth efficiently in......

Blog No comment - 07Feb

Emerging Trends in Fiber Optic Technology: A Comprehensive Guide for European Telecom Operators

Emerging Trends in Fiber Optic Technology; In an era where data transmission speed, reliability, and efficiency are more critical than ever, fiber optic technology continues to be the backbone of telecommunications. As the demand for 5G, IoT, and high-speed broadband accelerates, telecom operators must stay......

Blog No comment - 06Feb

Fiber Optic Cable Installation: Why Blowing Machines Outperform Traditional Methods

In the world of telecommunications infrastructure, efficiency, cost reduction, and long-term sustainability are key factors that drive innovation. The process of fiber optic cable installation has evolved significantly over the years, with cable blowing machines revolutionizing the industry. Best Fiber Optic Cable Installation Equipment is......

Blog No comment - 03Mar

Advancements in Fiber Optic Technology: Improving Bandwidth and Transmission Rates

Fiber optic technology has revolutionized the way we communicate, providing faster and more reliable data transmission over long distances. The use of fiber optic cables has become increasingly popular in recent years, and the technology continues to evolve at a rapid pace. In this article,......

Blog No comment - 03Mar

Fiber Optic Cable Installation: The Future of High-Speed Data Transmission

In today’s digital-first world, the demand for high-speed, secure, and reliable data transmission is growing exponentially. Whether it’s for telecommunications, data centers, military applications, or medical technology, efficient data transmission is critical for modern infrastructure. Fiber optic cable installation has become the backbone of modern......

Blog No comment

11 reasons why the future belongs to fiber optic

11 Reasons Why the Future Belongs to Fiber Optic “The future belongs to fiber optics!” This bold claim is backed by compelling reasons. Fiber optic technology is not just an upgrade—it’s a transformative infrastructure shaping how we connect, communicate, and consume information. Here are 11......

19″ Rack Cabinet

What is a 19” Free Standing Rack Cabinet? 19” free standing rack cabinets provide a robust, cost-effective enclosure solution. PDU mounting or connectivity on both the front and rear of the cabinet. The Free Standing 19” Rack cabinets are ideal for high-density data center environments,......

5 Fan Facts About the Fiber Optic Cables

Fiber optic cables are a type of cable that use glass or plastic fibers to transmit data. Here are some interesting facts about fiber optic cables: Speed: Fiber optic cables are capable of transmitting data at much faster speeds than traditional copper cables. This makes......

Advancements in Fiber Optic Technology: Improving Bandwidth and Transmission Rates

Fiber optic technology has revolutionized the way we communicate, providing faster and more reliable data transmission over long distances. The use of fiber optic cables has become increasingly popular in recent years, and the technology continues to evolve at a rapid pace. In this article,......

All about fiber optics

What does a fiber optic cable do? A fiber optic cable is a type of cable that uses glass or plastic threads to transmit data. These threads, or fibers, are extremely thin and are surrounded by a protective coating. They are able to transmit data......

Best Fiber Optic Cabling Installation Practices Guide

Fiber optic cabling installation is a complex process that requires specialized knowledge and equipment. Here are some best practices for fiber optic cabling installation to ensure a successful and reliable installation: Plan the Installation: Before starting the installation, it is important to plan......

Cable Blowing by Pressurized Air / Fiber Optic Cable Blowing Procedure

Cable Blowing (Sometime called air assisted cable blowing, Cable Blowing by Pressurized Air, air blowing, jetting and all these words are describing method of cable blowing with pressurized air) Cable Installation has been always a challenge for installers. There are several method to lay the......

Cable Blowing Lubricant

Cable blowing lubricants are specially formulated lubricants used to lubricate cables as they are being pulled through conduits or other tight spaces during the installation process. The lubricant is applied to the cables before they are pulled, and it helps to reduce friction and make......

Cable Blowing Machine work

Cable blowing machines, also known as a jetting machine or fiber optic cable blowing machine, is a device used to blow cables, such as fiber optic cables, into ducts or conduits. The machine works by using high-pressure air or water to propel the cable through the......

Cable Spooling Machines: The Ultimate Guide to Efficient Cable Handling

In industries such as telecommunications, energy, manufacturing, and infrastructure, the need for Cable Spooling Machines have never been greater. Traditional manual spooling methods can lead to inconsistencies, labor-intensive processes, and increased cable damage. This is where cable spooling machines revolutionize operations by ensuring precise, automated, and......